In a year dedicated to the slogan “Production Leap with People’s Participation,” Mobarakeh Steel Company (MSC) has once again solidified its position as the driving force of the national steel industry by registering a remarkable record in quality indices. Achieving a quality yield of 95.87% in the first seven months of the current year is news that goes beyond mere statistics; it testifies to the health of production lines, organizational maturity, technical synergy, and the unwavering commitment of human capital within this massive industrial enterprise. This achievement was realized while the steel industry grapples with numerous challenges, including energy restrictions and international sanctions. Yet, by shifting its paradigm from “product control” to “process management,” MSC has defined new standards in product quality.

Paradigm Shift: Prevention Strategy and Root Cause Analysis Yaser Haji-Heidari, Senior Manager of Quality Control and Sustainability at MSC, views this success as the result of a gradual, scientific path based on organizational synergy. Outlining the company’s macro-strategies in the quality domain, he stated: “This year, our primary focus has been on the precise identification of quality bottlenecks, root cause analysis of non-conformities, and, most importantly, prioritizing ‘prevention’ over ‘correction.’ Our colleagues across all production areas, with their responsible and quality-centric approach, have played a decisive role in realizing this goal.”

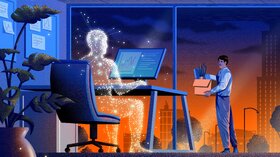

Pointing to the vital role of modern technology in process control, Haji-Heidari added: “Today at MSC, by leveraging advanced monitoring tools, data mining in analyzing line performance information, statistical analysis, and implementing the Six Sigma approach, faster and more accurate decision-making has been made possible for technical teams.”

According to the Senior Manager of Quality Control, increasing quality yield at MSC does not merely mean producing healthier products; it signifies an elevation in organizational maturity and the alignment of units in creating value for the customer. He emphasized: “We are pursuing this trend within the framework of a ‘Quality Sustainability Roadmap’ so that improvements are not temporary but are institutionalized within the system structure. MSC has always been a pioneer of innovation in the country’s steel industry, and now, relying on the knowledge and experience of its human capital, it continues the path of quality excellence with strength.”

A Jump in Indices and Direct Impact on Competitiveness Continuing the report, Gholamreza Kamali, Senior Production Manager at MSC, clarified the technical and economic dimensions of this achievement by providing precise statistics on the upward trend of indices. He noted: “The product quality yield index, which stood at 93% in the year 1402 (2023-2024), reached 95.8% with a significant leap during the first seven months of the current year. This improvement, resulting from a significant reduction in non-conforming products, is one of our key objectives that directly impacts profitability, brand reputation, and the company’s competitiveness.”

Regarding the executive measures taken to reach this figure, Kamali explained: “To achieve this goal, we placed systematic, comprehensive, and preventive approaches on the agenda. Technical parameters and their acceptable limits were redefined, and operational instructions were revised to be accessible to all employees. in some projects, using management tools and control charts, deviations were identified and corrected before they led to the production of defective products.” He also listed factors such as “smart goal-setting by top management,” “commitment and sense of responsibility of human resources,” “employee training and empowerment,” and precise execution of Preventive Maintenance (PM) programs as the main pillars of this success, expressing gratitude for the efforts of frontline production staff.

Integrated Quality Chain: From Ironmaking to Final Products MSC’s success is not the result of isolated performance but the outcome of a focus on quality across all links of the production chain. Alireza Ki-Yeganeh, Quality Control Manager, pointing to a 1.13% growth in the overall product quality index compared to the previous year—reaching the highest level in three years—said: “By identifying and prioritizing points affecting final quality and through direct, immediate interaction with production units, we have drafted stricter internal standards. Measures such as completing the ‘Atlas of Defects’ in Steelmaking and Hot Rolling areas, compiling this atlas for the Cold Rolling area, and optimizing inspection stations have been major steps toward standardizing defect detection.”

At the beginning of the production chain, Daryoush Rashidi, Ironmaking Area Manager, considered the continuation of the path to quality excellence as a guarantee for production sustainability and increased competitiveness in cost price. He emphasized that the Ironmaking area has solidified its position as a leader in quantity and quality by focusing on the satisfaction of downstream customers (Steelmaking) and precise control of product technical characteristics.

Steelmaking and Casting: The Beating Heart of Quality Abbas Mohammadi, Steelmaking and Continuous Casting Area Manager, described the actions taken in this area as extensive and technical. Listing 13 key measures in the first six months of the year, he stated: “Continuous monitoring of chemical composition, optimization of ferroalloy and aluminum consumption, and the use of modern and innovative refractory materials have led to uniformity in final product quality.” Mohammadi added: “In the production of special grades such as automotive and tinplate grades, by optimizing the metallurgical process and adding corrective compounds, the amount of non-conforming product has decreased, and customer satisfaction has increased. Furthermore, increased cooperation between production units, the laboratory, and the sales unit has drastically increased decision-making speed in quality-related cases.”

Hot and Cold Rolling: Responding to Strategic National Needs At the end of the production chain, where the final product takes shape, sensitivities are doubled. Ali Hajian-Nejad, Hot Rolling Area Manager, pointing to the shift in market taste, said: “This valuable quality record was achieved while in recent months, the trend of orders for hot-rolled sheets has shifted towards producing critical dimensions and hard grades, doubling the importance of this record. Management of production and maintenance processes, alongside the unsparing efforts of colleagues, allowed us to add another golden page to the company’s honors despite sanctions and energy limitations.”

Mohsen Esteki, Cold Rolling Area Manager, emphasizing the strategic importance of special grades for the automotive and home appliance industries, stated: “A shortage of these grades could have posed a major challenge for the country. However, by forming specialized working groups, statistically analyzing defects, and implementing Six Sigma projects, we succeeded in increasing quality in cold-rolled, galvanized, and color-coated products.” He cited measures such as optimizing the annealing process, resolving refractory issues in annealing furnaces, using high-quality silicone rubbers, and optimizing paint conditions as technical solutions that led to reduced defects and increased customer satisfaction.

Future Horizon The achievement of a 95.87% quality yield at Mobarakeh Steel Company sends a clear message to the national industry: Quality is not accidental; it is the result of planning, knowledge, and commitment. The managers and employees of this massive industrial complex are determined to continue the path of excellence with strength, relying on these achievements and continuous investment in technology and human capital, preserving Mobarakeh Steel’s position as a model of quality in the region and the world.

نظر شما