تولید ورق های MSC

-

Leading the Green Transition in the Steel Industry

MSC’s Comprehensive Strategy for Sustainable Water Management

This report outlines MSC’s comprehensive water strategy, demonstrating how wastewater substitution and record-breaking efficiency of 2.2 m³/t of slab have paved the way for zero river dependency upon the arrival of seawater

-

Mobarakeh Steel Company Reports Revenue Growth Amid Strategic Restructuring

Mobarakeh Steel Company (MSC), the Middle East’s largest steel producer, once again showcased a powerful performance in its half-year financial statements ending in September 2025.

-

National Honor for MSC: Localizing Slab Cutting Machines—A Model of Industrial Productivity

Mobarakeh Steel Group has once again proven its pioneering role in industry and self-sufficiency by securing the “Top Project Award for Improving Productivity in Iran’s Mines and Mining Industries” at the 11th National Productivity Award conference. This achievement, attended by the Head of IMIDRO’s Board of Directors and a group of the country’s technology activists, specifically highlighted the major accomplishment of localizing the design and manufacture of Slab Cutting Machines.

-

Elevating Brand Value via Global Norms

Mobarakeh Steel Adopts Global Standards for Brand Excellence

In the highly competitive landscape of the global steel industry, Mobarakeh Steel Company (MSC) is elevating its commercial strategy by prioritizing customer experience alongside production excellence. Reza Heidari, the company’s Deputy of Sales and Marketing, emphasizes that adhering to consumer rights has evolved from a mere legal formality into a critical strategic necessity for leading organizations aiming for global excellence. He argues that in modern trade, a seamless and pleasant purchasing experience is essential, as international clients view access to transparent information and fair dispute resolution as fundamental rights.

-

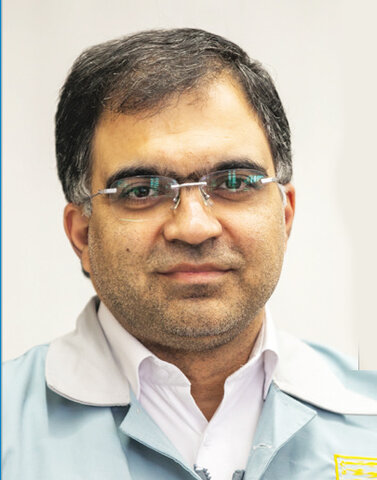

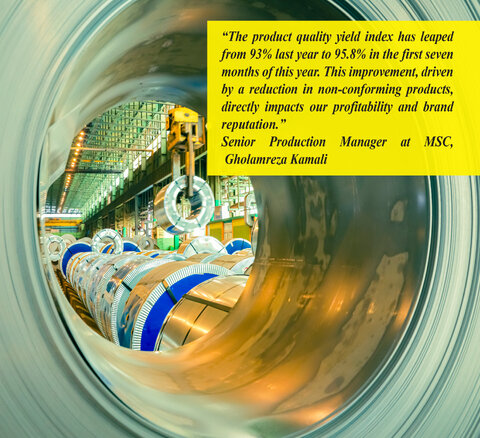

A Leap in Production Indices

Historic 95.87% Quality Yield Record

This report outlines MSC’s latest achievement in raising product quality yield to 95.87%, a success realized through a paradigm shift from “correction” to “prevention” and technical synergy across all production lines