Transitioning from Traditional Steels to Advanced Alloys: A Comprehensive Technical Analysis of History, Production Processes, and Expert Insights. In the complex ecosystem of materials engineering, corrosion has always been recognized as a primary factor in infrastructure degradation and the loss of national capital. Although surface engineering and cathodic protection have been classic solutions to combat this phenomenon, the emergence of a new generation of steels has shifted the governing paradigm of steel structure design.

On the other hand, the offshore industry, ranging from hydrocarbon extraction platforms to wind turbine farms, is known as one of the most challenging arenas of structural engineering, requiring materials that exceed conventional standards. In such a rigorous atmosphere, material selection becomes a critical issue for guaranteeing structural integrity and human safety.

The following report provides a detailed analysis of the historical evolution, physical metallurgy, and production processes of two strategic grades, S355MLO and S235J2W, which have recently been localized at Mobarakeh Steel Company (MSC).

S355MLO Steel: The Armor of Oceans and Offshore Structures

The development of Offshore series steels is a story of materials science keeping pace with human engineering ambitions. Until the mid-20th century, most oil platforms were constructed in shallow waters and tropical regions such as the Gulf of Mexico, where engineers relied on ordinary shipbuilding steels or normalized carbon-manganese grades.

However, the commencement of oil exploration in the North Sea in the late 1970s changed the equation. Confrontation with 30-meter waves, continuous storms, and near-freezing water temperatures exposed the weaknesses of traditional steels. Older steels required high thickness and high carbon percentages to achieve high strength, which reduced weldability and made the structure susceptible to hydrogen cracking and brittle fracture.

Disasters such as the capsizing of the Alexander Kielland platform in 1980, caused by fatigue crack growth in one of its braces, are considered turning points in the history of marine engineering . These incidents demonstrated the necessity of achieving a steel that simultaneously possessed high strength, lower weight, and superior toughness at sub-zero temperatures. In response to this challenge, metallurgists developed TMCP (Thermo-Mechanical Control Process) technology, introducing the S355MLO grade as a reliable solution.

Standard Analysis and Technical Nomenclature

Among the grades introduced in the European standard EN 10225 (Weldable structural steels for fixed offshore structures), the S355MLO grade is a reference material. structural steels for fixed offshore structures,” the S355MLO grade is a reference material. An analysis of this alloy’s nomenclature reveals its precise nature:

S: Structural application.

355: Minimum yield strength of 355 MPa.

M: Produced via Thermomechanical Rolling.

L: Indicates toughness and impact resistance at Low Temperatures.

O: Specific to EN 10225, confirming the alloy has passed all rigorous tests for Offshore applications.

Physical Metallurgy and Microstructural Architecture

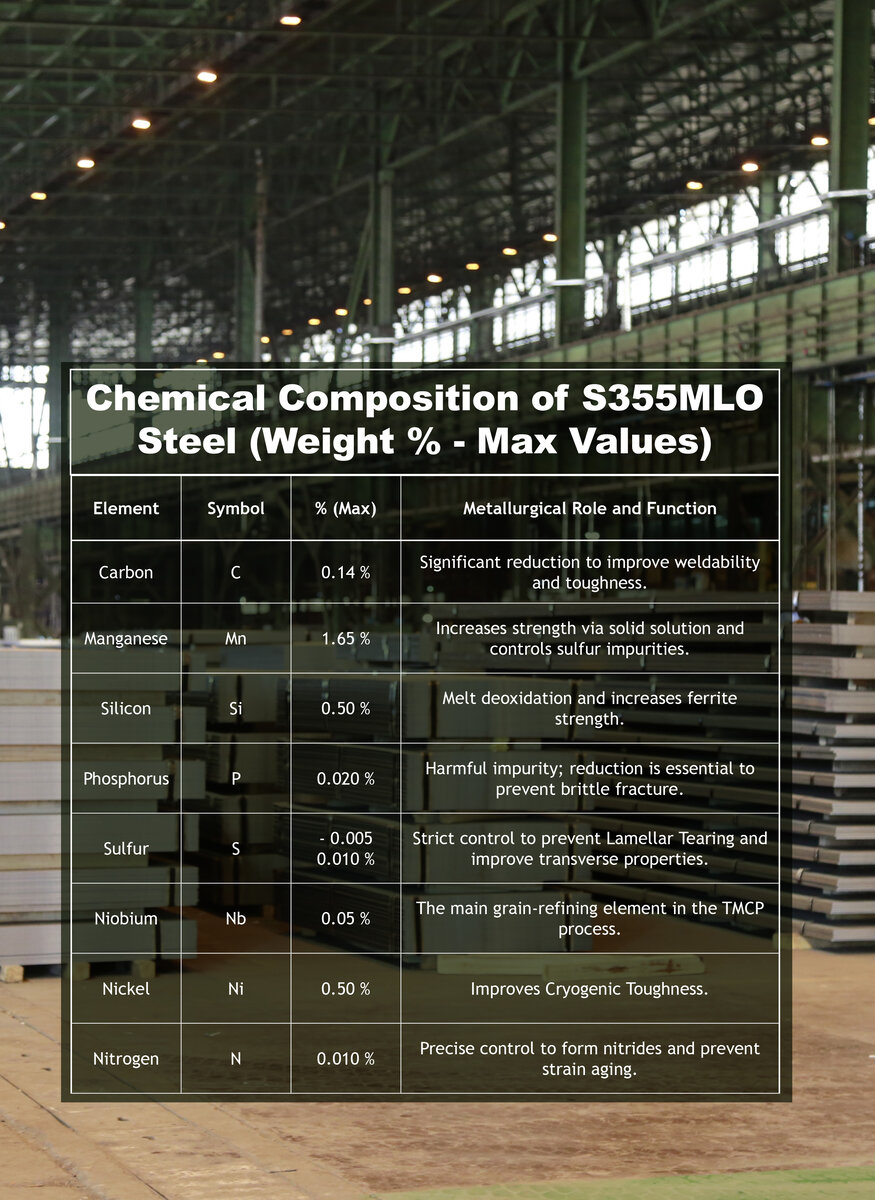

The primary distinction of S355MLO compared to conventional structural steels lies in the concept of “metallurgical cleanliness” and the strategy of “grain refinement.” The ultimate goal in designing the chemical composition is the maximum reduction of carbon and Carbon Equivalent (CEV) to enhance weldability without sacrificing mechanical strength.

To achieve this, elements such as Niobium (Nb), Vanadium (V), and Titanium (Ti) are utilized. These micro-alloying elements form carbide and nitride precipitates at grain boundaries, preventing austenite grain growth during rolling. According to the Hall-Petch relation, reducing grain size is the only mechanism that simultaneously increases strength and toughness. Furthermore, Sulfur and Phosphorus must be kept to the absolute minimum to prevent the formation of brittle phases.

Mechanical Properties and Advanced Fracture Mechanics

Unlike conventional structural steels, S355MLO is required to pass the Charpy V-Notch impact test at temperatures of -40°C or -50°C (per project specs). This requirement ensures that the Ductile-to-Brittle Transition Temperature (DBTT) is very low, exhibiting ductile behavior even in the coldest oceanic waters.

Additionally, the CTOD (Crack Tip Opening Displacement) test is mandatory to determine the extent to which the material can absorb energy before unstable crack propagation occurs. Furthermore, to combat the phenomenon of “Lamellar Tearing” in thick T-joints, this steel is produced with guaranteed through-thickness properties (Z-Direction).

Production Process Description: TMCP Technology and Fabrication Requirements

The production of this grade begins with secondary metallurgy, where the melt undergoes vacuum degassing to reduce dissolved hydrogen to less than 2 ppm. Calcium treatment (Ca-Treatment) is also performed to globularize sulfide inclusions.

In the controlled rolling stage, deformation occurs in the non-recrystallization region of austenite, causing grains to elongate and “pancake.” Immediately after the final pass, the Accelerated Cooling (ACC) system uses an engineered thermal shock to prevent grain growth, creating ultrafine ferritic-bainitic microstructure.

Regarding welding, the most critical limitation is sensitivity to high-temperature heat treatments. Any reheating above 580°C can destroy the fine-grained structure, drastically reducing mechanical properties.

Strategic Applications in Offshore Industries

In the oil and gas industry, this steel is the primary material for constructing Jacket Platforms, particularly at the Nodes. In the renewable energy industry, S355MLO is a key material for building Monopiles for offshore wind turbines, which are subjected to dynamic loads from turbine rotation and wave impact.

S235J2W Steel: The Alchemy of Atmospheric Resistance and Architecture

The history of Weathering Steels dates back to 1910, when researchers discovered that adding small amounts of copper to steel increased its resistance. In 1916, ASTM proved that combining copper with phosphorus reduced corrosion rates. In 1933, U.S. Steel introduced the commercial brand COR-TEN, primarily aimed at solving corrosion issues in coal wagons.

A historical turning point occurred in 1964 when prominent architect Eero Saarinen used this steel without coating in the design of the John Deere World Headquarters, transforming it into an aesthetic element of modern architecture . Over time, a new version with reduced phosphorus (similar to Corten B) was developed for heavy structures, and the European standard EN 10025-5 introduced the S235J2W grade as an optimized version.

Global Atlas of Weathering Grades

Understanding the global family of these steels is essential. In American standards (ASTM), grade A242 (equivalent to Corten A) with high phosphorus is used for decorative facades, while A588 (equivalent to Corten B) is used for heavy structures and bridges. In Japanese standards (JIS), the famous SPA-H grade exists, from which almost all shipping containers worldwide are made. In the European standard, the S235J2W series is ideal for architecture and cold forming due to higher ductility, while the S355 series is used for pedestrian bridges and main beams.

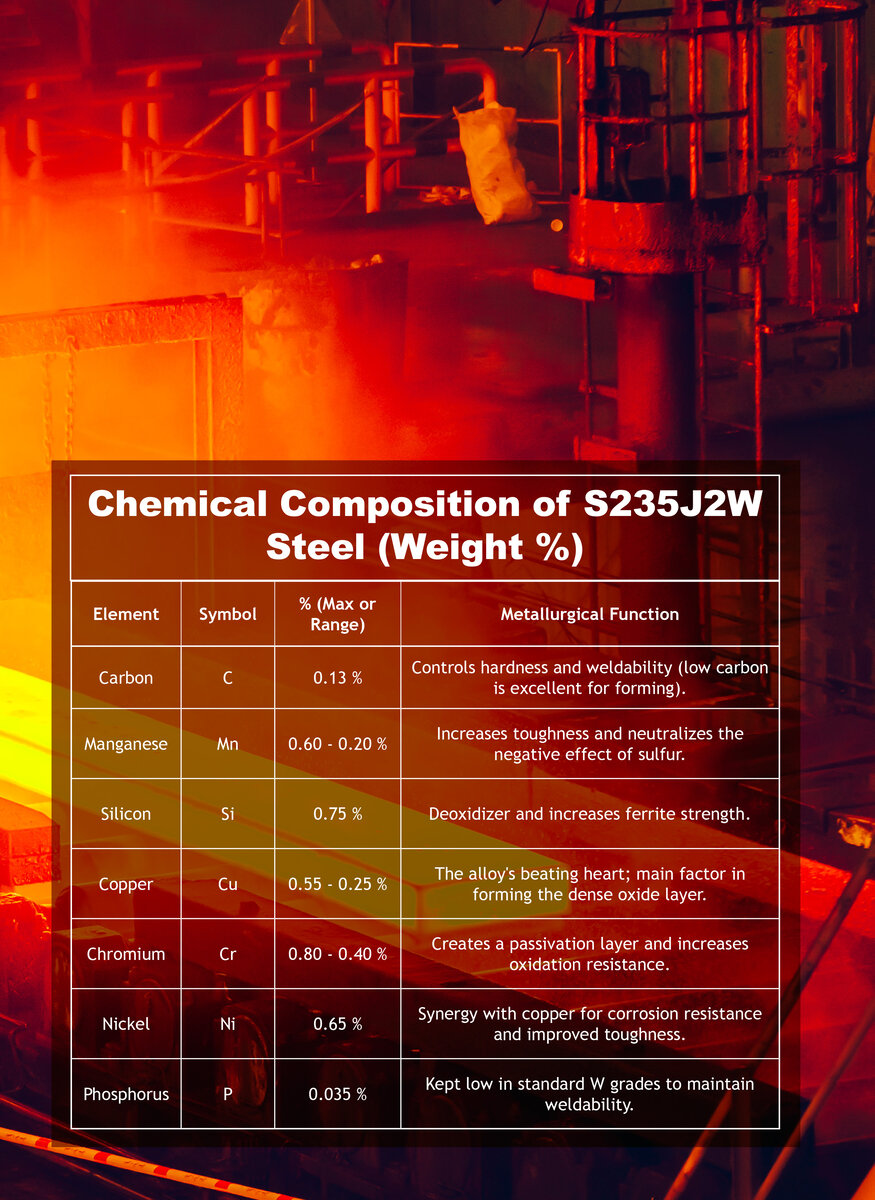

Technical Description and Patina Mechanism

The fundamental difference between S235J2W and ordinary steel lies in the microstructure of the rust. In ordinary steel, iron oxide is porous. However, in S235J2W, alloying elements (Cu, Cr, Ni) form an amorphous, highly dense layer of oxy-hydroxides called “Patina.” This layer reduces oxygen and moisture permeability to zero. The color transformation process takes 18 to 36 months to complete, transitioning from yellowish-orange to dark brown.

Engineering Benefits and Challenges

Using this grade offers long-term economic justification (LCC) by eliminating the costs of sandblasting, initial painting, and maintenance. Additionally, the “self-healing” feature means that if the surface is scratched, the patina layer regrows to repair the scratch. However, limitations exist: this steel should not be used in environments with very high chlorides (less than 2 km from the sea) or environments where the steel remains constantly wet. Furthermore, the issue of staining on underlying concrete surfaces during the initial years must be managed with proper drainage.

The Localization Narrative: Expert Perspectives on the Production Process at MSC

The production of these two advanced grades at Mobarakeh Steel Company is the result of a multifaceted and precise engineering effort. Below, the details of this process are narrated by the managers and technical experts involved in this project.

Alireza Molavizadeh, Manager of Metallurgy and Production Methods, announcing the successful production of these grades, stated that in line with the strategic goal of expanding the product portfolio, grade S235J2W was produced for the first time in the country in a wide range of dimensions (thickness 2 to 16 mm) in accordance with the EN 10025-5 (2019 edition) standard. He explained that due to the presence of copper and chromium, this product has service life several times longer than conventional carbon steels in corrosive atmospheres (EN 10025-5). Regarding the S355MLO grade, Molavizadeh emphasized that this special grade was designed and added to the product basket with the aim of making domestic industries independent of imports, tailored for final applications in construction, bridge building, as well as marine and offshore structures.

From a commercial and market perspective, Gholamreza Yazdani, Head of Hot Products Sales, explained that market demand was the starting point for this innovation. Noting that industrial contractors have needed durable steel for corrosive environments for years, he predicted that due to the cost-effectiveness of this product, a significant share of the market would be allocated to it. Yazdani added that producing this product eliminates the need for importing special steel sheets—currently imported from China, Turkey, and India—thereby preventing currency outflow and offering high export potential.

The product design process involved specific technical complexities. Hamed Tamizifar, Product Design Expert, explained regarding the S355MLO grade that due to customer requirements for coastal structures and stricter requirements than the standard (specifically the impact test at -40°C), the analysis design and rolling processes were carried out following extensive studies and simulations to ensure full compliance with the international standard EN 10225.

Regarding metallurgical principles, Babak Shahriari, Head of Thermoprocess and Product Design, explained that the high resistance of the S235J2W grade is due to the formation of a continuous and adherent oxide layer (Patina), influenced by chemical analysis and environmental conditions. He noted that the presence of elements such as chromium, copper, nickel, and phosphorus contributes to the stability of this layer. Regarding S355MLO, Shahriari added that its production was carried out via Thermomechanical processing (TMCP), yielding a final product with a measured yield strength ~450 MPa (exceeding EN 10225 minimum of 355 MPa) and an impact energy of 95 Joules at -40°C, exceeding standard requirements. Additionally, Ehsan Sadeghi, Metallurgy Expert, pointed out a crucial technical note: the optimal atmospheric condition for patina formation is a continuous wet and dry cycle; constantly wet environments or those containing chloride ions can destroy the patina layer, in which case the use of nickel and molybdenum is essential.

Production challenges in the steelmaking and casting areas were significant. Seyed Farzad Teimouri, Continuous Casting Process Expert, stated that to achieve a high-quality S235J2W product, casting parameters must be precisely adjusted, as the presence of copper and chromium makes this steel sensitive to segregation and surface cracks. He explained that adjustments to average cooling in the mold, the use of mold powder with low fluorine and phosphorus content, and oscillation control were implemented to prevent longitudinal cracks and sticking.

Hossein Mohammad Ghasemi, Secondary Metallurgy Production Expert, emphasized that producing atmospheric corrosion-resistant steel requires precise refining processes and non-metallic inclusion control, which was successfully achieved by updating secondary metallurgy and ladle furnace process instructions.

Complementing the steelmaking discussion, Amir Gorji, Steelmaking Production Process Expert, noted regarding S355MLO that strict controls were applied during melting preparation and slag tapping. In secondary metallurgy, anti-corrosion properties were improved by precisely adding alloying elements (Cr, Ni, Cu) and reducing harmful elements. He added that chemical segregation was prevented in continuous casting by controlling speed and secondary cooling. Behnam Adibi, EAF Production Head, referring to the internal grade 5548 (S355MLO), stated that the presence of chromium, copper, nickel, and niobium is essential in this grade. Given the high cost of alloy additives, precise calculations and control measures during tapping were implemented to achieve alloying at the lowest cost by preventing raw material wastage.

The final and decisive stage for mechanical properties is hot rolling. Masoud Nasiri, Hot Rolling Line Manager, stated that the Hot Rolling unit enabled the production of these new products by ensuring equipment readiness and conducting effective inspections. He attributed the rolling of these products to the efforts of all colleagues and announced readiness to include these grades in routine hot rolling schedules.

Detailed technical rolling aspects were described by Seyed Mahmoud Mani, Hot Rolling Process Engineer. Regarding S235J2W, he explained that given the variety of thicknesses (8 to 15 mm), a comprehensive review based on simulations was conducted to ensure stable production without stoppage risks, and necessary provisions were made for the strip head shape entering the coilers. Regarding S355MLO, Mani stated that achieving the target temperature along the hot rolling line was critical for attaining mechanical properties and reducing residual stresses. He added that after simulating production feasibility, trial production was carried out in three stages for thicknesses of 10, 12, and 15 mm, resulting in successful compliance with design conditions. Based on the mechanical properties of the produced coil, planning was done for sheet production in the shearing lines.

Finally, Mohammad Rahmati, Environmental Expert, addressed the environmental aspects of this achievement. He explained that MSC produced the S235J2W grade in line with the goal of reducing greenhouse gas emissions by 30% by 2031 (1410 Iranian calendar) and achieving Green Steel by 2050. Rahmati noted that this product minimizes Volatile Organic Compound (VOC) emissions by reducing the need for painting and maintenance, and its longer lifespan leads to reduced demand for new steel production and conservation of natural resources, aligning with the strategies of leading global companies like SSAB and Nucor.

نظر شما